Diamond Dressers

Single point Diamond Dressers

The EZ single point diamond dresser offers the assurance to dress universally. We recommend to choose the EZ single diamonds large enough, because single diamonds when subjected to the task, wear rapidly when dressing small, medium and large grinding wheel diameters and widths. Single point diamond dressing tools are suitable for flat dressing of grinding wheels as well as for dressing profiles.

Download Brochure Cluster Type Multi Point Diamond Dresser

EZ Cluster Type Multi Point Diamond Dressers are an economical substitute for large carat weight single point diamond dressers. Also, smaller diamonds are less expensive than large Diamonds. Single or Multiple layers of clusters containing multiple diamonds set in patterns of 3,5,..21 Small Several Grades of Diamonds according to request or Application. It gives rapid-dressing without scoring and produce consistent even surface on the grinding wheel.

Download Brochure Grit type Multi Point Diamond Dresser

EZ Diamond grit impregnated dressers have been developed from multi-point dressers.In contrast to the latter they are manufactured from crushed diamond grit rather than a larger number of small natural diamonds.It contains large number of diamond particles. The advantages of the diamond impregnated dresser lie in its exceptional sharpness which results from sharp edges and points of the broken diamond grit.

Download Brochure Blade Type Multi Point Diamond Dresser

EZ Blade type diamond dressers are basically conceived from the multi - point wheel dressing concept as an extension to the areas with a stringent control demand on quality & economy. Blade type dressers are best suitable for forming (angular/radius) of grinding wheels. On heavy-duty grinders especially center less grinders, often the demands are high both on quality and productivity

Download Brochure EZ CVD-MCD Dressing Blades

EZ CVD & MCD BLADES Manufactured with CVD or MCD Type Synthetic Needles.

The main advantage of CVD & MCD Needles is Thermal Conductivity.The thermal conductivity of CVD & MCD is most superior to that of Natural diamond

It helps greatly to consistency of Performance by drawing away heat from the contact zone between CVD or MCD dressing tool and grinding wheel.

Download Brochure Disc Type Multi Point Diamond Dresser

EZ MULTIPOINT DISC DRESSERS are normally used on smaller grinding wheels for internal grinding machines. The diamonds are set evenly in rows across the periphery of the disc. First class Needle shaped Diamonds, Natural diamonds & Blocky shaped Grit Diamonds are used, set in a special sintered bond. After one row of diamonds become flat/worn, by turning the roller further new tips are used for dressing,thus ensuring clean equal dressing.

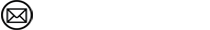

Download Brochure Chisel Type Single point Profile Dresser

EZ Profile dressers are also known as EZ Chisel type Diamond Dressers. EZ Profile Dressers are used for the accurate profiling and copy dressing of grinding wheels. Whenever EZ Blade dressers canít meet these requirements due to specific grinding wheel geometry precision profile Dressing tools are the solution. Our EZ Chisel Type Diamond Dressers are manufactured with specially selected higher quality natural diamonds, which are ensure the optimum tool life.

Download Brochure Matrix - Chisel Type Single point Profile Dresser

EZ Matrix Chisel Tools are widely Accepted, Trusted and Used by Industries in India and as well as Reputed Overseas clients

EZ Matrix type chisel diamond dressers are manufactured by using Carefully Selected Diamonds for applications of High Precision wheel Forming or Profiling. EZ matrix type Profile Diamond tools are used for

profiling and re-profiling of wheels with high accuracy on Matrix thread grinding, Nowell and Reishauer

machine. These chisels are available in Flats and Radius form.

Download Brochure